BBB BHP-20 and 21 Steerer Tube Extender

|

| BHP -21 for 1 1/8" steerer tube and 28.6mm stems |

Made in Taiwan and marketed by those wonderful Netherlandish folks at BBB.

It's one way of lengthening a threadless steerer tube that's too short.

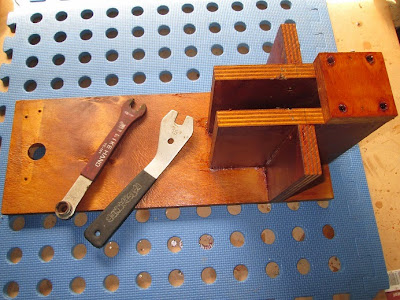

Here's another way, not by BBB in this case but they do make something similar.

|

| Another sort of steerer extender. |

This type of extender works fine but the clamp bolts are highly visible and very ugly. Clamping the separate stem as high as possible on the extension may be too high. Clamping lower leaves some of the extension showing above the stem, waiting to get you in the groin when you crash.

The BBB BHP-20/21 does not use an external clamp. It fits down inside the steerer tube and is fixed in place by a sliding wedge system just like an old fashioned quill stem. It's an especially good solution for a threadless steerer but it can also be used with a threaded steerer,

When using this extender with a threadless steerer you will continue to set the

preload on the Ahead type headset bearings by selecting a stack of headset spacers below the stem and

adjusting the top cap. Using the standard preloading process is one of the great conveniences of this product.

With a threaded steerer, the preload is set as usual by the headset's threaded top bearing cup and locknut. The extender acts only as a quill with a maximum height of 75mm. You have a choice of separate stems with various rise and reach but the quill height is fixed during the fitting process. There are quill type extenders from other makers which allow more height than 75mm and can be raised or lowered at any time. Many users of threaded forks will still prefer the classic look of a one piece quill stem.

|

| How it is made. |

Here are its components. It's claimed to be all 6061 aluminium alloy except for the long stainless steel wedge clamp bolt and the shorter top cap screw. The main body of the quill has a 10mm wall thickness which makes it acceptably strong and rigid. The 75mm stack of shiny rings adapt the quill to the stem clamp diameter. They range in depth from 20mm to 5mm. You decide how much longer you want your steerer tube to be and slide off rings as necessary to suit. The less length you need, the more the quill sinks into your steerer tube. I guess that the minimum insertion depth is at the bottom of the 75mm ring stack. Fewer rings equals greater insertion which can only be good for strength and rigidity. The rings are split to accommodate compression by the stem clamp and keyed on the inside to match a groove in the back of the quill.

|

| Arranging the split and keyed rings for a 45mm extension |

|

You will need to remove the star nut in your steerer tube before fitting this extender. A sharp 9mm bit in a portable drill will destroy the swaged connection between the top star shaped spring and the threaded nut core. Both top and bottom spring will then usually tilt in the tube and be easily removed with pointy pliers. You can try driving the star nut all the way through with a long drift but that gets very hard if your steerer tube is thicker walled down at the fork crown. Star nuts are cheap and you really should have a spare on hand just in case you want to change things back in the future.

This extender

must not be used with carbon fiber steerer tubes. If you have an alloy steerer tube, check first to be sure the quill will fit. Sometimes alloy steerers have thick walls and a small ID.

I'm sure I would not use this or any other steerer extension on any sort of bicycle used for hard off-road work. However, I think it would be fine for on-road use.

The BBB extenders definitely work with steel 1 1/8" steerers of 25.4mm ID and steel inch steerers of 22.2mm ID. But not with old French steerers of 22mm ID.

|

| Tightening the wedge bolt. Original spacers still in place on the steerer. Cane Creek 40 headset and Problem Solvers locking headset spacer for convenience. |

Use plenty of grease when assembling, particularly on the sliding wedge surfaces and the screw threads. A 6mm allen key tightens the wedge clamp bolt. The manufacturer quotes no torque figure for the clamp bolt. Use your imagination, bearing in mind that the sliding wedge is made of aluminium with aluminum threads. The threaded hole for the top cap screw is inside the bottom of the 6mm hex.

|

| Looks neat. Nothing visible to suggest the presence of the extension. | | |

It remains only to add headset spacers until the top of the stem clamp is 3mm or so above the top of the new extension. Then tighten the top cap screw with a 5mm allen key as you'd usually do to preload the headset bearings. Torque the stem clamp screws to manufacturers specs.

Summary:

BHP-20 is labelled 22.2/25.4. It fits inside an inch steerer tube of 22.2mm ID and needs a stem with a 25.4mm steerer clamp (or a stem with a 28.6mm clamp and a 25.4mm shim adapter)

BHP-21 suits most modern bicycles and is labelled 25.4/28.6. It fits inside a standard

1 1/8" steerer tube of 25.4mm ID and takes a stem with 28.6mm (or 1 1/8") clamp.

Weighs 250g.

Available at time of writing from

Wiggle UK at the following prices.

USD 13.85 GBP 9.18 AUD 18.08